IMPORTANT - Read this before using a Japanese knife

Every now and then a customer will return to the store with a damaged tip or chipped edge. Even if the problem is not very big, it happens often enough that we want to address the issue in this section.

When using a Japanese knife with a thin blade, the edge should always be in motion when you cut. Under no circumstance should you push the blade through the produce without the edge beeing in motion. Also, do not twist or wiggle the blade to pry apart the produce. If you press, twist or wiggle the blade, forcing it, a lateral strain on the thin edge easily occurs. An edge usually withstands quite a lot when it cuts straight from the top down, while moving forwards or backwards. This is because you have the entire blade above the edge that backs it up and that absorbs and distributes the stress. In a lateral force, there is only the leaf-thin edge, and no goods that capture and absorb the force. The hard edge will therefore flex as much as it can, but when the load becomes too great, a chip will come out of the edge, or a piece of the tip will break off.

This is not something that is covered by the warranty but is a case for a sharpening service. We sometimes get inquiries about whether the steel is incorrectly heat treated on a knife that has been damaged. Of course, defects can occur, but it is extremely uncommon. As the above problems are much more common, we always refer to a grinder that sharpens by hand on Japanese whetstones. If it had been a matter of incorrect heat treatment, the problem remains even after resharpening, and in that situation we would of course look into the matter more closely.

We take responsibility for our products, but since the very charm of the knives consists in its delicate edges, users can easily have different expectations of what 'a knife should be able to do'. This is because our European knife tradition is noticably different from the Japanese one. European knives are soft, thick and durable while Japanese knives are thin, hard and delicate.

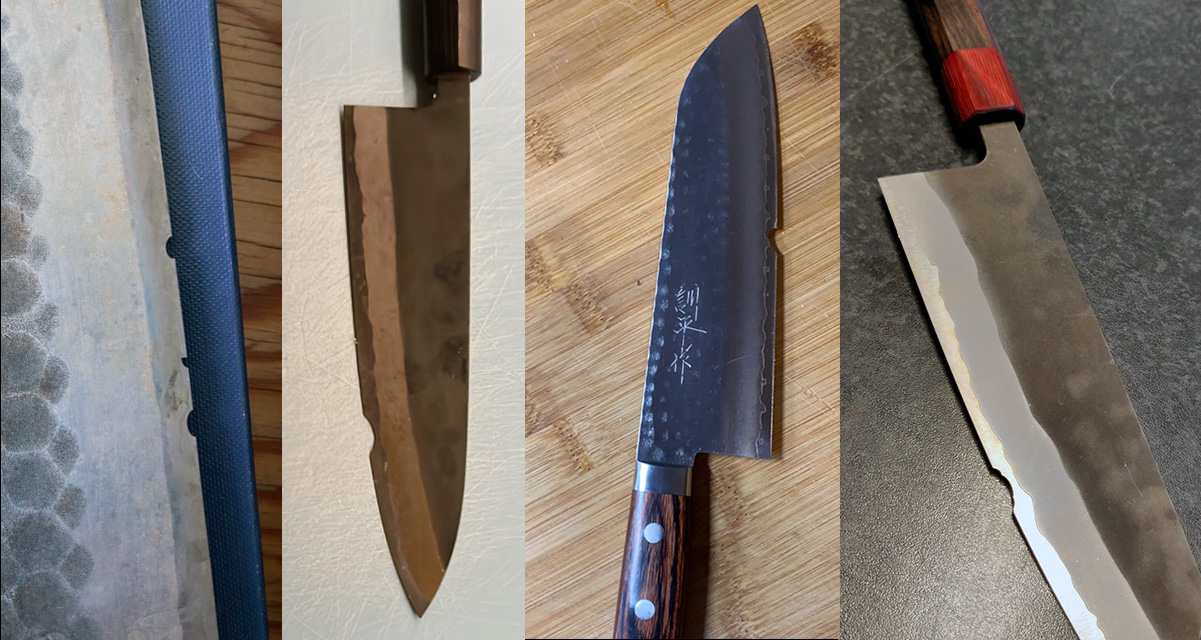

The following picture shows examples of what it can look like when an edge is damaged. This is typical damage for a knife that encountered a resistance greater than what the edge was able to absorb with its flexibility. When the edge has flexed as much as it can, and the force continues to press against the steel, it will chip away which may look like the damage caused in these images.

Buying a Chef's Knife - How Should I Think?

Are you looking to buy your first premium knife? The range on the market is large and it can be difficult to know what attributes a knife should have to suit you. However, these questions can help you a bit when it comes to deciding what is right for you.

1. Carbon steel or stainless steel?

A little further down in the knife school, there is a more detailed explanation of the differences between carbon steel and stainless steel. The overall differences, however, are that the carbon steel is easier to sharpen and it takes a great edge, but at the same time loses its sharpness a little earlier than a stainless steel that has the same hardness. The carbon steel will also oxidize and get a patina while the stainless steel remains shiny and nice looking. The wise choice is therefore stainless, although many users are looking for the feeling and rustic look that carbon steel brings.

2. What type of steel should I have?

This topic is also described in more detail below. Exclusive Japanese steels can be hardened to high HRC (hardness) and can for that reason be forged with thin edges that have steep angles. It gives the knife unsurpassed cutting properties, but at the same time makes the edge more sensitive. If you are looking for a knife that should be absolutely razor sharp and maintain sharpness, you also need to be careful with how you handle the knife so that you do not knock small chips out of the edge. The lower on the hardness scale you go, the more durable the blades will be, but at the same time they will not keep the sharpness as well. What is right for you? A good middle ground is usually a stainless steel with a relatively high hardness around 59-62 HRC. A hardness of 62-65 HRC is extremely hard, and if you go down towards 56-58 HRC you are talking about medium hard blades. Classic European knives often have soft steels with about 54-56 HRC, which makes it difficult to maintain sharpness over time, but the advantage is that they can withstand really rough handling.

3. Which handle?

The Western handle is usually seen on European knives, although it is also common on Japanese knives. It gives the knife good weight thanks to full tang and stainless steel rivets. The balance point is often in the middle of the bolster and fits well for you who hold the knife in the middle of the handle. For this type of handle, it is usually appropriate to keep your thumb and forefinger in the middle of the bolster or perhaps slightly in front of it. The oriental handle has no metal in it and is therefore lighter than European handles. The balance point always ends up in front of the handle and often a few centimeters into the spine. It gives the knife perfect balance if you pinch with your thumb and forefinger a bit into the blade. If you want to keep a more classic grip in the middle of the handle, the knife can be experienced as a bit front-heavy. There are also hybrid ahndles that are a fusion between the western and the oriental. The design is reminiscent of the Japanese handles, but here you choose to put a metal bolster and often also a metal plate at the back of it. This is done to move the balance point backwards and to give the knife a little more weight.

4. Finish on the blade.

Damascus steel, polished, black kurouchi or maybe hammered structure? These choices are mostly of cosmetic interest and have a relatively small impact on the knife's cutting ability. Choosing a beautiful blade in damascus steel increases the visual feeling, but at the same time the price will increase. Therefore, think about how important the look is to you.

Choosing a knife model

As you have probably already noticed, there are a variety of chef's knives on the market. You may have already browsed through our range and are unsure of which knife model is best for your needs? Based on our experience, we will therefore give you some concrete tips on how to choose a well-balanced set of knives. The guidance we present is our personal advice and you are therefore wise to think about these suggestions based on your own food culture, taste and liking.

1. If you are going to buy a single knife.

With a single knife, you are easily limited in the kitchen. A sturdy chef's knife with a 24 cm long blade solves most things, but some feel that the long blade can be a little awkward. However, you get used to it quickly and for many, a 24 cm chef's knife is the best choice. If you go down in length, the chef's knife with 21 cm is a common choice. It is a little easier to work with but falls short when you want to slice a large steak.

Many people choose to use a model called santoku. This knife model is found among most manufacturers and is a very popular Japanese chef's knife. Traditionally, the blade length is 16-18 cm. The tall blade and the rounded tip make this knife very versatile. It is ideal for chopping and slicing vegetables, poultry and meat, but can be perceived as a bit short when you are slicing larger pieces of meat. Santoku is fast becoming a favorite in the kitchen.

2. If you have decided to acquire two knives.

Here we recommend a traditional chef's knife with a slightly larger blade, which is complemented by a santoku knife treated above. Some people choose to replace the santoku knife with a pure vegetable knife. The vegetable knife is characterized by a completely blunt tip and is almost rectangular in its shape. The blade length varies between 14 and 18 cm depending on which size you feel most comfortable with. The advantage of a vegetable knife is above all the high blade. There is plenty of room for the knuckles and you can therefore keep a high pace without having to worry about accidents. The rectangular shape also allows you to chop larger volumes of fruit and vegetables at the same time. As a side kick to the vegetable knife or santoku knife, we recommend a traditional chef's knife with a blade length between 21 and 25 cm. This is the knife model that sells best in Europe and it is well suited for cutting fine slices of meat.

If you want to supplement with a third knife our choice definitely falls on a small and handy pairing knife. The length of a pairing knife varies between 8-12 cm. A short small peeling knife is used in practice only to peel and peel off marks from vegetables, etc. If you go up in length to 12 cm, you get a knife that is good for pork fillet, chopping garlic but of course also for peeling things. Here you get to think about how you want to use your smaller knife.

4. The fourth choice in your new knife set may look a little different.

If you like to cook from scratch, we gladly recommend a flexible fillet knife that is great for filleting fish. If you do not feel that unprepared fish is your area, then a handy bread knife might come in handy.

Basically, it is you who uses your knives who can best determine which knife or knives work best. However, we hope that we have been able to help you along the way with your difficult choices. Contact us and we will be happy to help compose a good set according to budget and needs.

Hardness of the blade

How hard a blade is is measured with a durometer and the result is stated in the unit HRC (Rockwell). Qualitative chef's knives have between 54 and 64 HRC, so even small differences in HRC can mean a big difference in hardness. This is not to say that a knife with a soft blade is necessarily worse than a knife with a high HRC. It all depends on what properties you are looking for in a knife. A soft blade with 54 HRC is easy to sharpen. The angle of the edge is around 20-25 degrees. Because the edge is soft, it is easy to sharpen until the knife has a satisfactory edge. The final sharpness of a knife with low HRC seldom becomes as sharp as that of a knife with high HRC, and the edge does not keep its sharpness for as long. To compensate for this, manufacturers usually make soft blades thicker and provide the edge with a blunter grinding angle. The increased steel mass gives the edge support and durability, but contributes to greatly impaired cutting properties compared to thin Japanese blades.

Knives with very hard blades can be sharpened at a much steeper angle and still maintain their sharpness during use (down to an angle of about 10 degrees). For this reason, Japanese chef's knives have become immensely popular in recent years. The downside, however, is that hard blades are harder to grind once they have lost their sharpness.

A hard blade is expensive to produce, heat treat and process into a finished blade. The advantage is that they are ground at a very steep angle and have very thin and fine blades (usually a 10-15 degree angle). They therefore become sharp as razor blades and are able to maintain this sharpness for a long time, as long as they are used for what they are intended for. If you start cutting in tougher materials, the sharpness will quickly wear off because there isnt alot of material in the edge. Another disadvantage of hard leaves is that they are more fragile. If you cut a soft blade into a hard object, plastic deformation will occur, meaning it has to move somwhere. It often chooses to dent. A hard steel does not have the same chance of deforming and will instead break off (popularly called 'chipping'). You then get everything from a small notch in the blade to a small shard that comes loose.

So, what do you learn from this? One conclusion is that knives have different areas where they shine. If you are careless and do not care about the sharpness significantly, then perhaps a European knife with a soft blade is preferable. If you instead want a sharp knife that keeps the sharpness but requires more care and caution, a Japanese knife is preferable.

Stainless or carbon steel?

Many knives are made from stainless steel, but we also have several knives that are not stainless. But why would you want a knife that can rust?

In order for the knife to have a sharp and fine edge, the steel needs to have a high carbon content. Coal is very prone to corrosion, which makes it difficult to use in humid environments. So-called 'stainless' steels therefore contain various additives such as chromium. Chromium contributes to rust protection and gives high gloss, which makes it an excellent additive in, for example, cutlery. The disadvantage is that chrome makes it very difficult to maintain the sharpness of the knife. When a steel is produced, there is therefore a balance between performance and rust inertia. Really cheap knives have a very low carbon content and are almost 100% stainless. Other steels with a higher carbon content can also be 'stainless', but here rust will be forced if left with moisture. The term 'stainless steel' should instead be called 'stain resistant steel'. You could also divide the steels into different degrees of rust inertia.

Carbon steel is different. There is often a total lack of chromium or other substances that counteract corrosion. Quality carbon steels have a carbon content of about 1%, which gives the possibility to give it an incredibly fine edge. The carbon steel often lacks vanadium, cobalt and other hard substances that help the carbon steel to maintain its sharpness. It can therefore be said that carbon steel becomes sharper than most stainless types, but loses its sharpness much faster. Then we have the 'problem' of corrosion. A fine Japanese carbon steel such as Shirogami and Aogami has low rust inertia. It may be enough to leave the leaf with moisture for 5-10 minutes for rust to start forming. The user must therefore make sure to wipe the blade dry after use. When the carbon steel is new and 'naked', it is extra sensitive and will react with most things. If you cut into proteins, a bluish or greenish patina will appear, while other raw materials can give tones of gray or brown. This layer, or patina, gives the blade some protection against corrosion. Of course it is not a very efficient rust protection but it is much better than when the knife is new. Some manufacturers choose to laminate the blade sides with stainless steel to completely avoid corrosion and patina on the blade sides. The edge is of course exposed in the same way as pure carbon steel blades.

To sum up, it can be said that carbon steel is a fantastic material with a great personality. The knives can be sharpened really sharp and are easy to keep sharp through regular sharpening or honing. The price for this performance is that you need to keep the blade dry when the knife has been used, and you must be comfortable that the steel will oxidize and get a patina. 'Stainless' steels are much easier to maintain, and are for many a more practical choice.

To clean kitchen knives

Make it a habit to always wash the knives under running lukewarm water when changing raw materials. When cooking is finished, you should wash and dry the knife dry with a towel. This is especially true if you have cut citrus fruits or if your knife is made of carbon steel. Acid and moisture can give even the most expensive blades discoloration and sometimes even rust.

You should never ever wash knives in a machine:

1. Dishwasher detergent contains abrasives that affect sharpness.

2. Dishwasher detergent contains salt so that it does not clump together. The salt can create ugly stains on the edge.

3. If a knife is in the cutlery stand, it hits other cutlery during the washing program and the edge can be damaged.

4. The strong jet of water can cause the sharp edge to scratch up the dish rack, which then begins to rust.

5. The heat during the drying program can affect the properties of the steel.

6. It is easy to injure yourself on a knife that is in a dishwasher.

Comparison of our chef's knives

Here is a partial list of the chef's knives we sell. The table is sorted by hardness of the blade. To interpret the table, you should keep in mind that most of our knives have very hard quality blades. The knives from Global are known for their hard blades, but still end up quite far down the scale due to the fact that we have so many other knives with high HRC.

An increase in HRC often means a higher price. This is because it requires more quality steel and an extensive hardening process to create a hard blade. Of course, the price picture is also affected by other factors such as the choice of handle, detail work and finish.

|

Knife |

Core steel |

HRC level |

Weight |

Model |

|

|

Miyabi 5000 MCD Black |

ZDP-189 | 66-67 HRC | 198 gr | Gyuto 20 cm | |

|

Akifusa PM |

SRS-15 | 64-65 HRC | 170 gr | Gyuto 21 cm | |

|

Akifusa Oriental PM |

SRS-15 | 64-65 HRC | 141 gr | Gyuto 21 cm | |

|

Hinoura Super |

Aogami Super | 64-65 HRC | 168 gr | Gyuto 21 cm | |

|

Akifusa AS |

Aogami Super | 64-65 HRC | Gyuto 21 cm | ||

|

Kurosaki Super |

Aogami Super | 64-65 HRC | 155 gr | Gyuto 21 cm | |

|

Moritaka Super |

Aogami Super | 64-65 HRC | 152 gr | Gyuto 21 cm | |

| Aogami#2 | 63-64 HRC | 240 gr | Deba 16,5 cm | ||

|

Ohishi Sakon |

SKD11 | 63-64 HRC | 173 gr | Gyuto 21 cm | |

|

Shiro Kamo Damascus |

Aogami#2 | 63-64 HRC | 167 gr | Gyuto 22 cm | |

|

Yoshikane SKD |

SKD | 63 -64 HRC | 143 gr | Gyuto 21 cm | |

|

Moritaka AO2 |

Aogami#2 | 63-64 HRC | 150 gr | Gyuto 21 cm | |

|

Shiro Kamo Black Dragon |

Aogami#2 | 63-64 HRC | 185 gr | Gyuto 22 cm | |

|

Goko Hamono |

Shirogami#1 | 63-64 HRC | 155 gr | Gyuto 21 cm | |

|

Shibata Kotetsu |

SG-2 | 62-63 HRC | 125 gr | Gyuto 21 cm | |

|

Kurosaki R2 |

SG-2 | 62-63 HRC | 160 gr | Gyuto 21 cm | |

|

Yaxell Gou |

SG2 | 62-63 HRC | Gyuto 20 cm | ||

|

Takamura Hana |

SG2 | 62-63 HRC | Gyuto 21 cm | ||

|

Ryusen Blazen |

SG2 | 62-63 HRC | 175 gr |

Gyuto 21 cm |

|

|

Takamura Blazen |

SG2 | 62-63 HRC | 175 gr |

Gyuto 21 cm |

|

|

Miyabi 5000 MCD |

SG2 | 62-63 HRC |

Gyuto 20 cm |

||

|

Miyabi 6000 MCT |

SG2 | 62-63 HRC |

Gyuto 20 cm |

||

|

Ikeda |

Shirogami#2 | 62-63 HRC |

Gyuto 21 cm |

||

|

Wakui |

Shirogami#2 | 62-63 HRC |

Gyuto 21 cm |

||

|

Yaxell RAN |

VG-10 |

60-62 HRC |

223 gr |

Gyuto 20 cm |

|

| Yaxell ZEN | VG-10 | 60-62 HRC | 215 gr |

Gyuto 20 cm |

|

|

Hiro Damascus series |

VG-10 | 60-62 HRC | 174 gr | Gyuto 21 cm | |

|

Ohishi VG-10 |

VG-10 | 60-62 HRC | 177 gr | Gyuto 21 cm | |

|

Takamura V10 Special |

VG-10 | 60-62 HRC | 158 gr | Gyuto 21 cm | |

|

Miyabi 5000 FCD |

FC61 |

~61 HRC |

190 gr |

Gyuto 20 cm |

|

|

Kashima RS-60 |

PS60 |

60 HRC |

Gyuto 21 cm |

||

|

Tamahagane SAN Kyoto |

VG-5 |

59-60 HRC |

Gyuto 21 cm |

||

|

Tamahagane Kyoto |

VG-5 | 59-60 HRC | Gyuto 21 cm | ||

|

MAC PRO |

CrMoVa |

59-60 HRC |

258 gr |

Gyuto 23,5 cm |

|

|

Masahiro NEO |

59-60 HRC | 147 gr | Gyuto 18 cm | ||

|

MAC Mighty |

CrMoVa |

58-59 HRC |

208 gr |

Gyuto 21 cm |

|

|

Tamahagane SAN |

VG-5 |

58-59 HRC |

165 gr |

Gyuto 21 cm |

|

|

Tamahagane 3-Ply |

VG-5 |

58-59 HRC |

228 gr |

Gyuto 21 cm |

|

|

Fujiwara FKM Series |

CrMoVa |

58-59 HRC |

165 gr |

Gyuto 21 cm |

|

|

Frost by Mora |

12C27 | 58 HRC | 158 gr | Gyuto 21 cm | |

|

Kashima Kihon |

CrMoVa |

56-58 HRC |

Gyuto 21 cm | ||

|

Global |

CrMoVa |

56-58 HRC |

171 gr |

Gyuto 20 cm |

|

|

MAC Superior |

CrMoVa | 56-58 HRC | 140 gr | Gyuto 20 cm | |

|

type 301 By F.A. Porsche |

CrMoVa |

56-58 HRC |

235 gr |

Gyuto 20 cm |

|

|

Sabatier K |

Z50C13 |

54-56 HRC |

198 gr |

Gyuto 20 cm |

|

|

Victorinox |

x50CRmo | 54-56 HRC | 135 gr | Gyuto 22 cm | |

|

Satake Houcho |

54-56 HRC |

95 gr |

Gyuto 17 cm |

||

|

Satake No Vac |

54-56 HRC |

Gyuto 21 cm |

|||